Asbestos

Asbestos can be described as a "supermineral." Its remarkable physical properties have contributed to its use in a number of building products. However, its amazing properties are diminished by its health risk. Airborne fibers of a certain size (not too big and not too small) can lodge in the lungs and slowly cause a number of different diseases over time. Diseases can occur in 3-5 years from very severe exposures although it is much more common for symptoms of the disease to occur over 15 or more years from the exposure.

Interested in learning more?

Repair, Encapsulate, Remove or Leave it Alone?

How asbestos is managed in the home depends on the material involved, the condition, disturbance or risk of distrurbance and comfort level of the homeowner. Fortunately there are very few forms of asbestos found in homes that require some action even when in good condition. How asbestos should be managed is specific to the material type and situation. Many forms of asbestos are best left in place until a renovation requires removal. You may have heard that it is safer to leave asbestos in place because sometimes asbestos air levels are higher after abatement. This erroneous belief originated from early USEPA studies when asbestos abatement was in its infancy. This may have been a result of the background levels from installation or previous improper removals rather than the removal being studied. Abatement methods are generally well-established and safe. Even when initial air clearance sampling fails, it is not difficult with additional cleaning and air-scrubbing to get airborne levels back to within safe limits. Ultimately, the decision to remove asbestos is driven by health concerns associated with the building residents or workers that will potentially be contacting the asbestos. In addition, sometimes asbestos removal becomes a peace-of-mind decision.

Tri-Tech offers the following

asbestos related services:

Asbestos can generally categorized into the following types:

- high risk materials that are readily identifiable based on appearance without testing (e.g. duct insulation, pipe insulation, heat/light shielding)

- potential high risk materials that should be tested (pipe insulation installed after the early 1960s)

- potential low to medium risk materials that are probably asbestos (e.g. cement shingles, 9x9 floor tile)

- potential asbestos materials that can be low to high risk depending on use and circumstances (e.g. sash window glazing)

- asbestos vermiculite containing materials that can be low to high risk depending on use and circumstances

- low risk materials that may contain asbestos (foundation window putty, roof flashing, door caulk)

Synthetic slate

may contain asbestos

How does asbestos testing work?

For bulk (sold) materials, a piece is submitted to a laboratory where it may be prepped as necessary (e.g. ashed/dissolved) and then the fibers are viewed under a microscope.

For air samples, air is filtered through a sample cartridge. The pump is calibrated so that a known volume of air is filtered. The filter is dissolved in the laboratory and placed on a microscope slide where the fibers are counted and converted to an air concentration. More about asbestos air testing.

boiler insulation

Pipe insulation is the most commonly identified form of asbestos in other buildings with legacy heating systems

Floor tile may be the most

common form of asbestos

in the home

asbestos-contaminated vermiculite insulation was used until the 1980s

Providing testing services for what is commonly referred to by flooring installers as a "Clean Air Certificate."

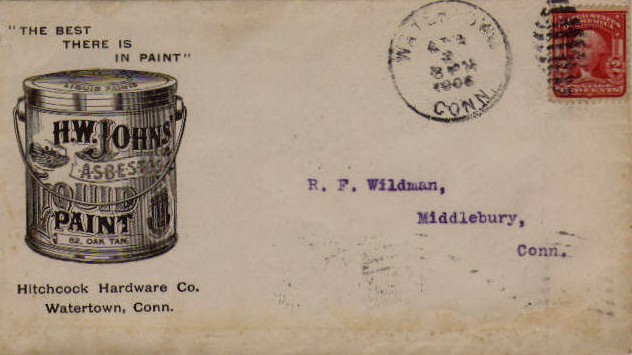

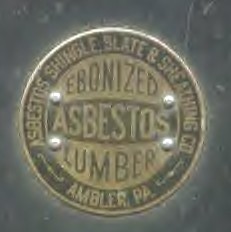

asbestos paint (for roofs/metals) advertised in the late 1800s

Asbestos inspections with testing of up to 3 samples starts at only $125!

Damaged asbestos pipe insulation doesn't need to be removed. Often health risks can be mitigated by patch and repair abatement methods. Infra-red thermography can be helpful with these projects because areas of cracked or gaps in insulation will be shown as "hot spots." Post-encapsulation and repair projects can also be scanned by IR camera to verify performance of the project as illustrated by the absence of hot spots on the insulation runs.